The Gas Spring is a Hydro - Pneumatic Adjusting Element with Pressure Tube, Piston Rod and End Fittings. It Contains High Pressurized Nitrogen.

As Compared to Conventional Coil Springs, Gas Spring has an Extremely Flat, Nearly Linear Characteristic Curve which Facilitates Uniform Comfortable Adjustment or Pivoting Movement. Also, it has Another Advantage Over Mechanical Springs is Damping. When Gas Spring is Installed Piston Rod Facing Downwards, During Extension it First Travels through Gas Portion and then through the Oil Portion. The Oil Dampens the Movement and Speed Reduces Considerably.

The High Pressure Nitrogen Acts with Equal Pressure on Surfaces having Different Cross - Sectional Area of Piston. This Produces a Force in Extension Direction. The Force Depends Upon the Charging Pressure.

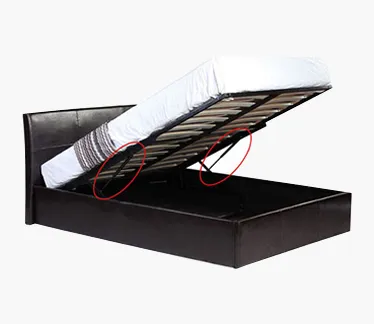

Gas Springs For Double Bed

Gas Springs For Double Bed Gas Springs For Double Bed

Gas Springs For Double Bed Gas Springs For Indica Dickey

Gas Springs For Indica Dickey Gas Springs For Over Lofts

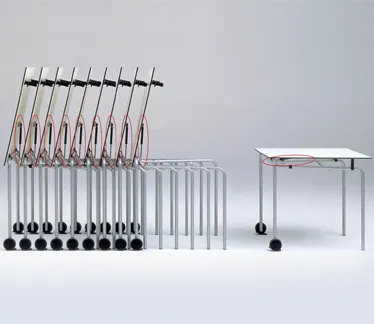

Gas Springs For Over Lofts Gas Spring for Folding Table

Gas Spring for Folding Table Gas Springs For Box Tools

Gas Springs For Box Tools Gas Spring For Automobile Safari Bonnet

Gas Spring For Automobile Safari Bonnet Gas Spring For Wave / Coverwave Soldering Machines

Gas Spring For Wave / Coverwave Soldering Machines Gas Springs For Hardware Fittings, Bed Frames, Wardrobes

Gas Springs For Hardware Fittings, Bed Frames, Wardrobes Gas Springs For Control Panels

Gas Springs For Control Panels Gas Spring For Bed Fitting

Gas Spring For Bed Fitting Gas Spring for Truck Tool Box

Gas Spring for Truck Tool Box Gas Spring For Vaccum Packing Machines

Gas Spring For Vaccum Packing Machines Gas Spring For

Gas Spring For Gas Spring For Textile Spares

Gas Spring For Textile Spares| APPLICATION IN VARIOUS SEGMENT | |

| Segments | Application |

Automobile |

Rear Hatch (Dickey), Bonnet |

| Furniture | Overhead lofts, Cabinets, Beds, Ventilators |

| Auto Bus Body Building | Luggage Compartment, Engine Flap, Roof top Ventilators, Spl. Mobile Van |

| Textile Machines | Opening Machine Doors |

| Generator Canopies | Canopy flap opening |

| Control Panels Machine Tool Covers |

Doors of various control panel Doors of oil filtration units, EDM wire cut machine flap, Blood analyser, Flaps of various machines |

| Hospital Furniture | Various beds, Opration tables, Bed side trolley, Lamps |

Garbage Chutes & systems |

Garbage chutes & Garbage handling collection of garbage from multi story building. |

| Counter balancer | Various equipments like tapping machine arms, ENT Microscope, Overhead hospital lamps, CNC machine arms. |

| Dairy Equipments | Flaps of Milk Chilling Plants |

| Metro rail Application | Control Panels |

| Construction Equipments | Lifting Doors of enclosed cabinets |

| Material handling Equipments | For Standing platform, For Handle. |

| Export | UAE (United Arab Emirates) |

| CAPACITY CHART | ||||||||

Model |

EXT Length (mm) | Stroke (mm) | Force (N) (F1) | Standard Strokes | ||||

| Min. | Max. | Min. | Max. | Min. | Max. | |||

| 615 | 86.0 | 360.0 | 25.0 | 140.0 | 50.0 | 300.0 | 60, 94, 140 | |

| 818 | 91.0 | 725.0 | 25.0 | 300.0 | 50.0 | 500.0 | 60, 94, 140 | |

| 1021 | 141.0 | 800.0 | 25.0 | 350.0 | 100.0 | 800.0 | 100, 150, 277 | |

| 1028 | 210.0 | 820.0 | 25.0 | 350.0 | 100.0 | 800.0 | 100, 150, 200 | |

| 1428 | 210.0 | 820.0 | 50.0 | 350.0 | 200.0 | 1750.0 | 100, 250, 300 | |

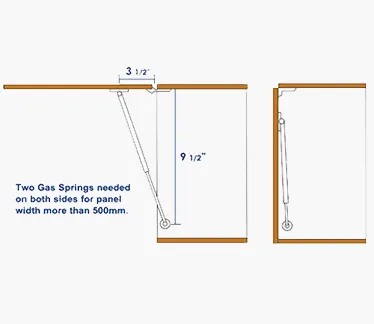

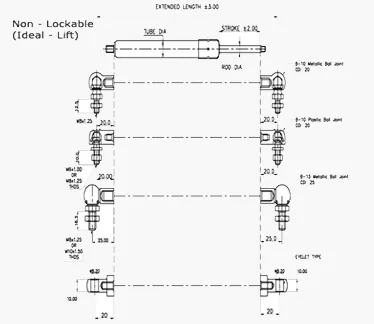

Gas Spring - Layout Diagram

Gas Spring - Layout Diagram Gas Spring - Layout Diagram

Gas Spring - Layout Diagram