Lockable gas springs have the mechanism that enables the piston rod to be locked at any position in its stroke. This mechanism is triggered by a plunger that is linked with the rod. When this plunger is pressed the rod becomes free to operate as compression gas springs. When plunger is released at any point in the stroke, the rod is locked in that position.

The Internal Design of the lockable gas springs consist of components such as piston rod, piston valve, cylinders, guides, seals etc. Inside Pressure is generated by gas(nitrogen) and oil inside the cylinder. These Gas Springs are applicable for Lockable Gas Springs, Gas Spring For Hospital Beds, Hospital Furniture, Dentist Chairs, Operation Tables, Labour Tables, Emergency Casualty Trolleys, Passenger Seats, Wheel Chairs.

Lockable Gas Spring For Hospital Beds

Lockable Gas Spring For Hospital Beds Lockable Gas Springs For Hospital Examination Couch Back Rest

Lockable Gas Springs For Hospital Examination Couch Back Rest Gas Springs For Hospital Furniture Overbed Tables

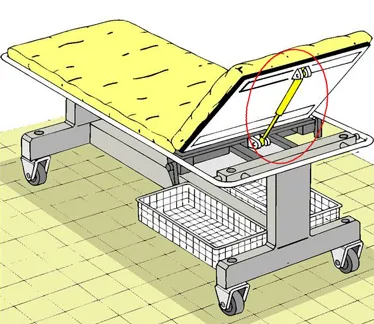

Gas Springs For Hospital Furniture Overbed Tables Lockable Gas Springs For Hospital Emergency Recovery Trolley

Lockable Gas Springs For Hospital Emergency Recovery Trolley Lockable Gas Spring For Dentist Chairs

Lockable Gas Spring For Dentist Chairs Lockable Gas Spring For Operation Tables

Lockable Gas Spring For Operation Tables Lockable Gas Spring For Labour Tables

Lockable Gas Spring For Labour Tables Lockable Gas Spring For Hospital Furniture Labour Tables

Lockable Gas Spring For Hospital Furniture Labour Tables Lockable Gas Spring For Emergency Casualty Trolleys

Lockable Gas Spring For Emergency Casualty Trolleys Lockable Gas Spring For Passenger Seats

Lockable Gas Spring For Passenger Seats Lockable Gas Spring For Wheel Chairs

Lockable Gas Spring For Wheel Chairs| APPLICATION IN VARIOUS SEGMENT | |

| Segments | Application |

Automobile |

Rear Hatch (Dickey), Bonnet |

| Furniture | Overhead lofts, Cabinets, beds, Ventilators |

| Auto Bus Body Building | Luggage Compartment, Engine Flap, Roof top Ventilators, Spl. Mobile Van |

| Textile Machines | Opening Machine Doors |

| Generator Canopies | Canopy flap opening |

| Control Panels Machine Tool Covers |

Doors of various control panel Doors of oil filtration units, EDM wire cut machine flap, Blood analyser, Flaps of various machines |

| Hospital Furniture | Various beds, Opration tables, Bed side trolley, Lamps |

Garbage Chutes & systems |

Garbage chutes & Garbage handling collection of garbage from multi story building. |

| Counter balancer | Various equipments like tapping machine arms, ENT Microscope, Overhead hospital lamps, CNC machine arms. |

| Dairy Equipments | Flaps of Milk Chilling Plants |

| Metro rail Application | Control Panels |

| Construction Equipments | Lifting Doors of enclosed cabinets |

| Material handling Equipments | For Standing platform, For Handle. |

| Export | UAE (United Arab Emirates) |

| CAPACITY CHART | ||||||||

Model |

EXT Length (mm) | Stroke (mm) | Force (N) (F1) | Standard Strokes | ||||

| Min. | Max. | Min. | Max. | Min. | Max. | |||

| 1028 | 177.0 | 650.0 | 25.0 | 250.0 | 200.0 | 850.0 | 45, 60, 120 | |

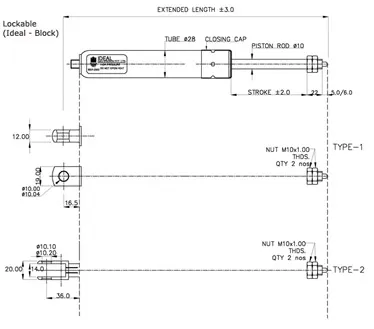

Ideal Block Diagram

Ideal Block Diagram