User Manual of Gas Spring

1. To ensur open position of a Flap / Dickey

2. Ease of human efforts to open a flap / dickey Gas Spring torque is more than the dickey torque

As Compared to Coil Springs, Gas Spring has an Extremely Flat, Nearly Linear Characteristic Curve, which Facilitates Uniform Comfortable Adjustment or Pivoting Movement.

Also, its Another Advantage Over Mechanical Spring, is Damping. When Gas Spring is Installed Piston Rod Facing Downwards, During Extension it First Travels Through Gas Portion and then through Oil Portion. The Oil Dampens the Movement and Reduces the Speed Considerably. However, the Extension Speed and Damping Characteristics Can be Adjusted as Per Applications Requirement.

Application : The Gas Spring has Wide Application Range, it Varies From Automobile to Machine Tools, Household Furniture, Over Head Filing Cabinat and Kitchen Cabinets. Also it Can be Designed as Per Specific Requirements.

Other Advantages and Benefits Are :

Automatic and Damped, Force Supported Opening

Automatic and Damped, Force Supported Opening Secure Holding in Place

Secure Holding in Place Compact Design

Compact Design Easy to Mount

Easy to Mount Maintenance Free

Maintenance Free Modern Technology

Modern Technology Fatigue Free

Fatigue Free Single Person Can Lift Heavy Doors Easily.

Single Person Can Lift Heavy Doors Easily.

In their technical design, gas springs must be customized for special applications – on the basis of specifications and drawings. Match your application and requirements with us. Our consultants will be glad to help you.

If possible, install gas springs so that the piston rod points down in the inactive state – unless they were designed for non-orientation specific installation. This will ensure optimum lubrication of the guide and sealing system at all times.

Mount the gas spring with piston rod facing downwards for better damping.

Mount the gas spring with piston rod facing downwards for better damping. Tight all mounting nuts / screws properly.

Tight all mounting nuts / screws properly. Allow free movement in hole, in case of clevis (Eyelet Type) end connection.

Allow free movement in hole, in case of clevis (Eyelet Type) end connection. Prevent side loads on gas springs this can cause bending of piston rod or early wear.

Prevent side loads on gas springs this can cause bending of piston rod or early wear. The tube must be protected from dents, & should not be deformed. As such damage could destroy the sealing systems.

The tube must be protected from dents, & should not be deformed. As such damage could destroy the sealing systems. If gas springs are fitted in applications where failure means risk of health or life, we recommend using additional locking mechanisms.This is customer responsibility.

If gas springs are fitted in applications where failure means risk of health or life, we recommend using additional locking mechanisms.This is customer responsibility. Unless specifically designed for tension loads, gas spring must not be loaded with traction forces.

Unless specifically designed for tension loads, gas spring must not be loaded with traction forces. Do not extend or retract gas springs beyond their design specifications.

Do not extend or retract gas springs beyond their design specifications. Ideal expect end users to test gas springs, because it is not possilble to simulate or anticipate the complate range of situations where our products may be used.

Ideal expect end users to test gas springs, because it is not possilble to simulate or anticipate the complate range of situations where our products may be used. High accelerations or velocities during extension or compression must not overload unit.

High accelerations or velocities during extension or compression must not overload unit. To prevent damage to the gas spring and to maximize its life span, please allow 10% margin to the standard stroke to reduce shock that is caused by the compression of gas. The margin can prevent damage on the gas spring when the piston rod touches the bottom surface and shortening a lifespan due to the impact by maximum gas pressure

To prevent damage to the gas spring and to maximize its life span, please allow 10% margin to the standard stroke to reduce shock that is caused by the compression of gas. The margin can prevent damage on the gas spring when the piston rod touches the bottom surface and shortening a lifespan due to the impact by maximum gas pressure Do the fitment of gas spring preferably from skilled mechanic.

Do the fitment of gas spring preferably from skilled mechanic. Operating temp. Range : (-20° C to + 80° C)

Operating temp. Range : (-20° C to + 80° C) Gas Springs are maintenance free. Do not grease or oil the gas spring.

Gas Springs are maintenance free. Do not grease or oil the gas spring. Piston rod must not be painted & should be protected against scratches, dirt & dent. As such damage could destroy the sealing systems

Piston rod must not be painted & should be protected against scratches, dirt & dent. As such damage could destroy the sealing systems Gas Springs are not to be fitted in any application other than specified

Gas Springs are not to be fitted in any application other than specified Unless specifically designed for tension loads, gas spring must not be loaded with traction froces

Unless specifically designed for tension loads, gas spring must not be loaded with traction froces

Insert screw driver tip in the clip as shown and pull the gas spring

Push the socket on ball pin to mount the gas spring

For a long service life, gas springs must not jam or be subjected to bending or lateral forces. We offer suitable end fittings, such as angle joints. They will ensure non-jamming alignment.

The functional safety of a gas spring comes mainly from the smooth piston rod surface and the seals that keep the gas pressure on the inside. Do not subject gas springs to bending stresses. You should not install gas springs that have been damaged in after-sales, mechanical processing. Welding on the gas spring, as well as contamination or paint on the piston rod can cause device failure. Avoid modifications and manipulations, impacts, tensile stress, heating, painting, and removal of the imprint. Be on the safe side: Do not install defective or improperly altered products.

IDEAL gas springs are designed for a default temperature range of -20°C to +80°C. Of course, there are also Gas Springs For more extreme applications.

Gas springs are maintenance-free! They do not require greasing or lubrication. They are designed for their corresponding applications and will work flawlessly for many years.

Store gas springs with the piston rod pointing down. Actuate the gas spring after 6 months of storage. Avoid damage: Do not transport gas springs as bulk material. Make sure not to contaminate gas springs with thin packaging film or adhesive tape.

Do not heat / open or put in openfire the gas spring, such act may lead to injuries because of high pressure.We are not responsible for any damages or any kind.

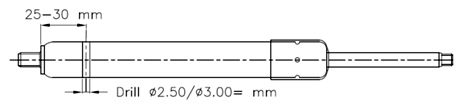

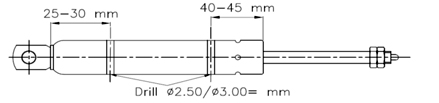

Gas spring consists mostly the metal which can be recycled, but firstly it should be depressurized. Please ask us about the disposal instructions. When gas springs are no longer needed, they should be disposed of in an environmentally correct manner. For this purpose they should be drilled, release the compressed nitrogen gas and the oil to be drained. For more specific details, please refer to our disposal instructions.

With gas spring fully charged with high pressure gas, non-compliance with this warning may lead to accidents , product damages, malfunctions, etc. Before using the spring make sure to fully understand and observe the warning below

Make a Drill in the gas spring tube as shown in above Drawing.

Make a Drill in the gas spring tube as shown in above Drawing.

+91 - 98505 85673

+91 - 98505 85673